Carbon black is a material consisting mainly of carbon, obtained from the partial combustion or thermal decomposition of hydrocarbons, consisting of spherical primary particles, uniformity of primary particle sizes within a given cluster and turbostratic* layers.

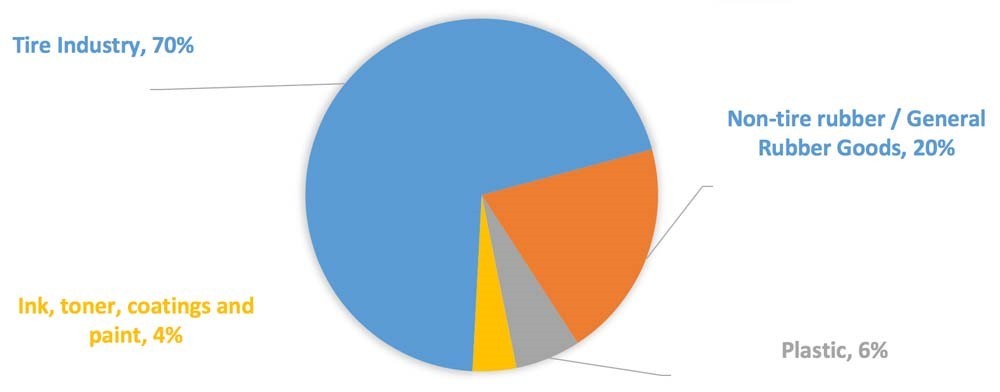

Carbon black is used in large quantities in the production of tires, plastics, various rubber products, paints and toner. The main factors driving the growth of the carbon black market are the demand from industrial rubber compounds, tire, construction and manufacturing industries. They are also widely used in the plastics, paints and coatings industry due to their physical properties such as color stability, solvent resistance, thermal stability.

There are three different types of formation in Carbon Black:

Particle – The smallest form of carbon black with a size in the range of 10-300 nanometers (nm).

Aggregate – The smallest combination of individual carbon black particles in the polymer compound. It is a random combination of multiple KS particles fused together forming chain-like branching clusters. Industrial grade carbon black aggregates range in size from 85 nm to 500 nm.

Agglomerate – A combination of loosely bound (with weak cohesive forces) but not fused aggregates. The size of the agglomerate ranges from 1 micron to hundreds of microns and much higher (in the case of pellets). The relative position of the aggregates within the agglomerate can be changed or separated by external mechanical force. Pellets themselves are artificially formed large agglomerates created by the pelletizing process.

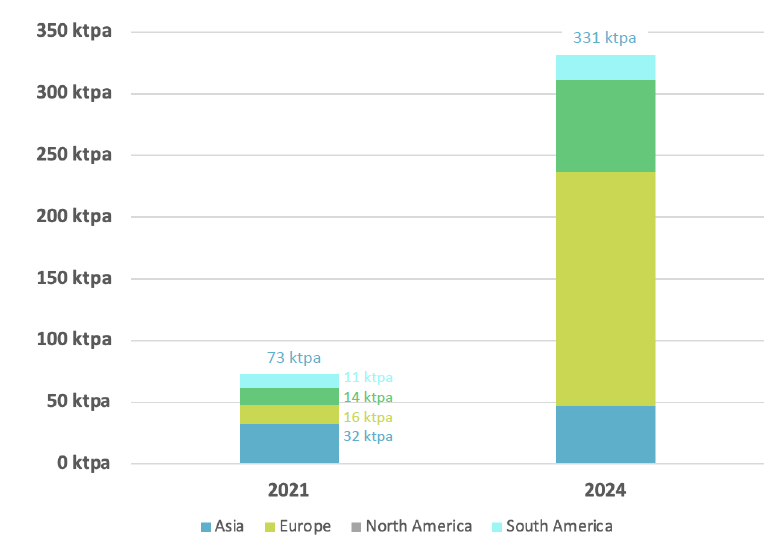

Europe is projected to surpass Asia in rCB production capacity by 2024/25.

In general, the view is that the main drivers of growth in Europe are “Sustainability and Economy”. Developed economies’ commitment to sustainable and environmentally friendly technologies is likely to be the main determinant of the future of the market.

In order to increase the use of recovered carbon black by industry and accelerate the development of the rCB industry, concerted efforts of all stakeholders involved in this field are needed. Regulatory constraints in major industries are mainly due to the lack of standardization of rCB. The good news is that ASTM is moving forward and developing specific standards for rCB. This is where the newly approved D36 standard from ASTM International’s Reclaimed Carbon Black Committee will provide a testing facility to help differentiate reclaimed carbon black products and provide a quality control tool for manufacturers and users.

The new standard (soon to be published as D8474) describes a thermogravimetric (TGA) technique for determining the organic residue, overall fixed carbon content and ash content in recovered carbon black.

Industry representatives on the committee noted that industry adoption of this standard could now be faster. They also say the market could grow rapidly, with the view that recovered carbon black could “complement or replace” conventional carbon black in many applications, including the production of more sustainable tires.

Considering that rCB is a partial and full substitute for virgin carbon black (VCB) in various industries, the market potential of rCB is determined by the existing VCB markets. According to various industry experts, worldwide vCB consumption over the last five years is estimated to be in the range of 11-13 million tons per year. The global carbon black market, valued at $17.5 billion in 2018, is forecast to grow at an annual growth rate of 3.5% until 2026, reaching $23.0 billion in 2026. According to the calculations, the global rCB market is estimated to grow by 2% annually until 2027, and assuming a 20% substitution rate with vCB, the annual volume of the global rCB market is estimated to be approximately EUR 3.5-4 billion.

Continental’s target of continuous reuse of its tires or input materials and its commitment that 100 percent of its tires will be refurbished or made of 100 percent recycled or other sustainable materials by 2050, and Bridgestone and Michelin’s desire to use 100 percent sustainable materials in their tires by 2050, could easily enable the market to reach 1 million tons by 2030. Of course, the rapid implementation of the standards mentioned above will be vital here.

The rCB composition is still not within the limits set by the CB4reach consortium. Therefore, most of the eco-tox studies in the carbon black dossier do not apply to rCB. New studies are needed by the registrant and the creation of new registries is urgently needed.

Last but not least, the sector, which is still in its infancy, needs awareness and willpower. You can be sure that #ICarbon, which continues its R&D activities for the technical development of rCB, will continue to develop methods that will meet the future demands to reduce costs and increase the quality of carbon blacks produced for a sustainable world.

Our series will continue with our articles on the technical and scientific interpretation of recycled carbon black…

Yours sincerely

* Turbostratic structure – The parallel layers appearing in the structure have a regular shape on the vertical axis, but their angular positions on each other are scattered and irregular. This structure is called “turbostratic structure”. The pores in the structure are formed due to voids caused by the irregular structure.

Sources:

https://polymer-additives.specialchem.com/

https://www.mordorintelligence.com/

https://sn.astm.org/updatehttps://weibold.com/

https://rcbrubber.com/

https://www.continental.com/