Efforts to tackle the challenges posed by waste tires and rubber have been ongoing for years. However, with the increasing awareness of sustainability, these initiatives are accelerating, and scientifically based outcomes are becoming more prominent. Over the past few months, we have begun to see tangible results of these efforts. The latest press releases from Bridgestone, Continental, and Goodyear in the last two months clearly highlight this progress.

These pioneering efforts by industry leaders are not only driving change within their respective companies but are also serving as a catalyst for the entire rubber sector, pushing it toward a more sustainable future.

Bridgestone: Advancing Tire-Derived Pyrolysis Technology

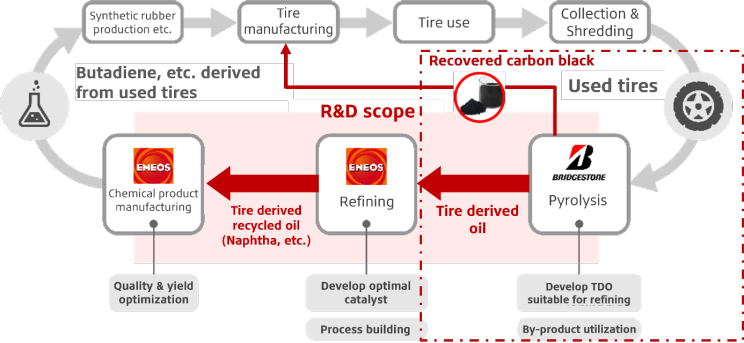

On June 8, Bridgestone Corporation announced in its press release that it has started producing tire-derived oil and recovered carbon black through pyrolysis at its test units established at the Bridgestone Innovation Park in Kodaira City, Tokyo.

This project is part of Japan’s New Energy and Industrial Technology Development Organization (NEDO) Green Innovation Fund initiative. It is one of two R&D projects focused on developing chemical recycling technologies using waste tires. Bridgestone is currently conducting validation tests on this project in collaboration with ENEOS Corporation.

This initiative also aims to promote the application of chemical recycling technologies for the high-yield production of chemical products such as butadiene, a key raw material for synthetic rubber.

For more details, you can access the press release here: Bridgestone Press Release

Continental: Introducing the Most Sustainable Mass-Produced Tire

On June 14, Continental announced that it has become the first manufacturer to launch a mass-produced tire with a very high proportion of sustainable materials.

The company introduced UltraContact NXT, its most sustainable series tire to date, incorporating up to 65% renewable, recycled, and mass balance-certified materials. Continental emphasized that this tire combines high sustainability with maximum safety and performance.

“By launching a tire with both a high proportion of sustainable materials and maximum EU tire label performance in mass production, we are setting a new industry benchmark,” the company stated. The UltraContact NXT is expected to be available at tire dealers across Europe starting this July.

As part of Continental’s Vision 2030 strategy, the company is committed to incorporating over 40% renewable and recycled materials in its tires by 2030, with a long-term goal of achieving 100% sustainable materials in all its tire products by 2050. UltraContact NXT is designed for both electric and internal combustion vehicles, offering the highest efficiency ratings and optimal mileage performance. It also carries the EV Compatible logo.

For more details, you can access the press release here: Continental Press Release

Goodyear: Pioneering Carbon Black from Methane Pyrolysis

On May 10, Goodyear Tire & Rubber Company announced the launch of the industry’s first tire to use carbon black produced via methane pyrolysis.

Goodyear unveiled a new tread formulation for its ultra-high-performance ElectricDrive™ GT tire in size 235/40R19. This new compound includes carbon black sourced from methane pyrolysis, developed in collaboration with Monolith.

Goodyear plans to expand the use of methane pyrolysis-derived carbon black to additional product lines in the coming years. Additionally, the company is working with Monolith to explore the potential applications of carbon black produced from waste-derived methane.

For more details, you can access the press release here: Goodyear Press Release

A New Era in the Rubber Industry

As seen in these recent developments, industry leaders are now providing concrete evidence of their sustainability efforts. These examples clearly indicate that the advancements in sustainable product development will only accelerate in the coming years.

How do we know this? 😊 Because as a technology innovator, ICARBON is already developing formulas and running projects in this field.

Best regards,

Erdem Mutlu – Founder of ICARBON